However, if you cut the bean in half thereby doubling surface area, the extraction rate would increase by a factor of two. Break the bean even further and the surface area would increase exponentially, until it becomes practical enough to brew.

By now you got the idea, which is that by creating smaller particles you increase the rate at which solubles can extract from the grounds.

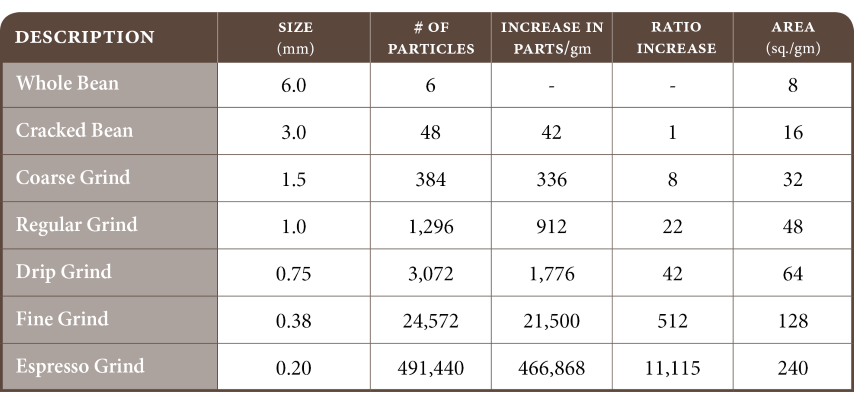

Table 1 below shows how the ratio of particle size increases over 10,000 times in an espresso grind when compared to the whole bean.

Table 1: Particle Size vs. Number of Particles per unit Weight

Source: Lingle, T. Brewing Handbook. SCAA

It is no surprise then, that creating smaller coffee particles increases surface area, such that there is a greater liberation of carbon dioxide gas (CO2) and absorption area for hot water to act upon. Smaller particles also shorten the distance from the center of each particle thereby increasing extraction of oils, solubles, and other flavoring materials.

The whole process of reducing whole particles into smaller ones is called "grinding" and can be done using number of different methods. There are a number of different type of grinders with perhaps the most common being blade and burr grinders.

Factors Influencing Grind

Several factors act on the bean and ultimately affect the way the coffee behaves during grinding. These factors include:

- Moisture content: Typically roasted beans that have been subjected to water quenching tend to be softer than air cooled ones. As a result, water quenched beans tend to distort unevenly during grinding and tend to produce inconsistent grind particles.

- Degree of roast: Typically beans of lighter roasts will be more pliable and tenacious than darker roasted coffee. It is the greater loss in moisture in dark roasts that makes beans more brittle and as such, produces a greater number of finer particles than lighter roasts.

- Bean brittleness: The origin of the coffee also affects how the bean behaves during grinding. Natural coffees will grind differently than wet processed coffees - given the same roast level. Also new crop coffees will always produce fewer fine particles than past crop coffees - due to differences in cell structure. Altitude also affects the way the bean will grind, since those beans grown at higher altitude tend to be denser than those grown at lower altitude.

Grinding Standards

In the 1940's, the US Department of Commerce established a testing procedure for measuring the distribution of particles. The equipment - called a RoTap - consists of four wire screens stacked on top of each other. When attached to a vibrating machine, particles inside the sieve fall through the various size screens to create a particle distribution.

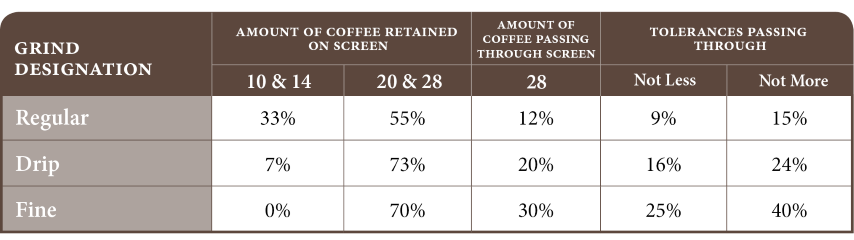

The procedure involves measuring 100g of roasted ground coffee and placing it on the top sieve and allowing the machine to shake for 5 minutes. After the cycle, all the sieves are removed and the coffee remaining in each sieve is weighed. Using this method a particle distribution curve can be calculated then classified. Luckily the US Department of Commerce has taken defined some of the most common grinding specifications. See Table 2 below.

Table 2: Recommended Coffee Grinds

Source: US Dept. of Commerce

Since grinding plays such a critical role in beverage quality, it's important to match the grind level the brewing method. Obviously espresso requires a much smaller particle size than say French Press. Also, always grind the coffee as needed as increasing surface area rapidly causes coffee to go stale.

References:

Lingle, T. The Brewing Handbook. SCAA